Mega Moulds Product

DECORATIVE PAVING BLOCK MANUFACTURING PLANT

You can contact us for the facility where you can produce all kinds of concrete paving stone, tile, curbstone, rain gutter, grasscrete, tactile pavings, and wall covering stones with the plastic moulds.

INVESTMENT DESCRIPTION

FACILITY WORKING VIDEO

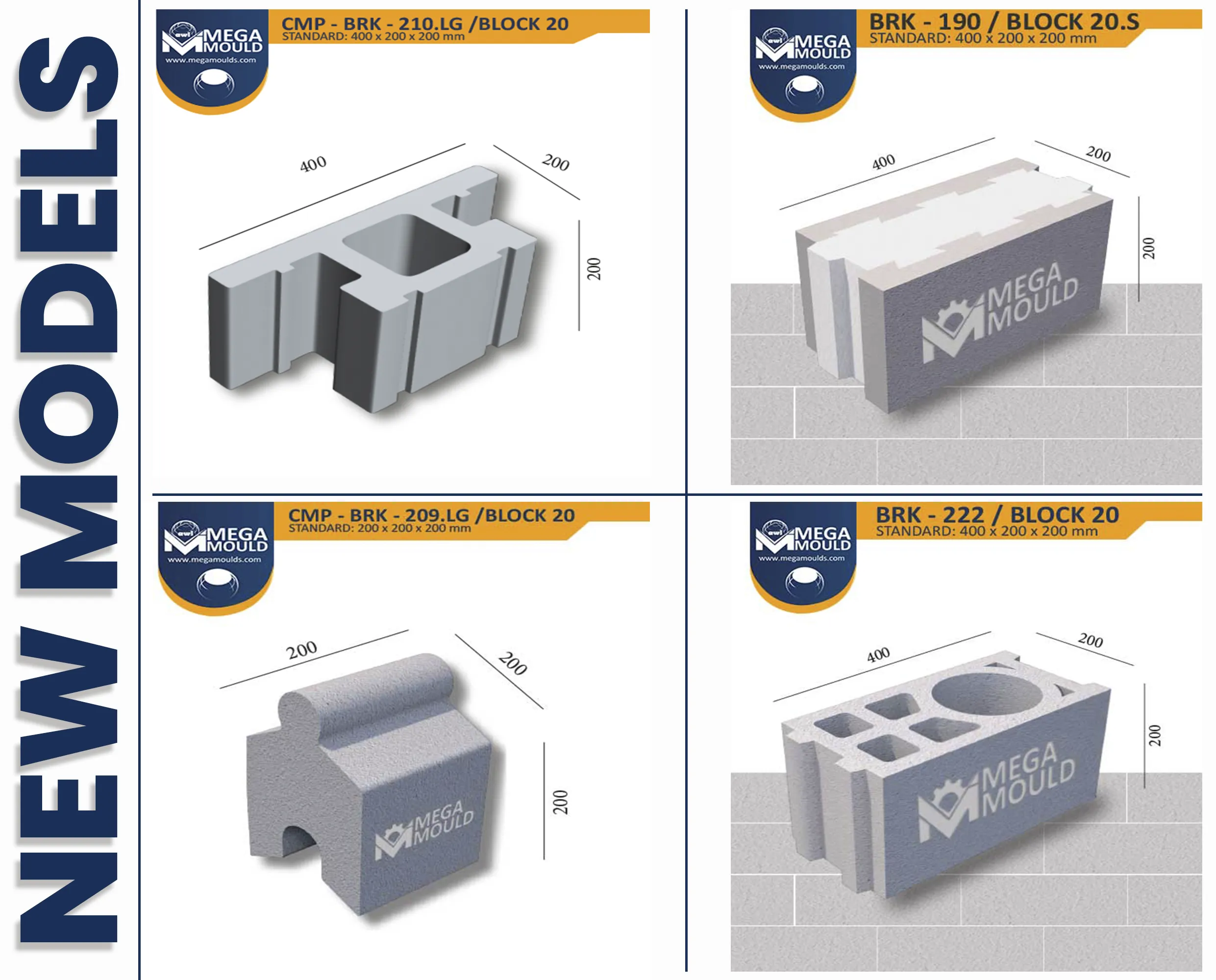

OUR MOULD MODELS

Plastic molds are produced using premium quality PP (polypropylene) raw material. this allows you to produce an average of 250 decorative paver blocks with correct use. While designing our plastic moulds, the necessary conical angle has been given to them so the blocks can be easily removed from the mold by the dismantling machine. In this way, the dismantling process does not cause any deformation in the blocks.

SOME EXAMPLES

Thanks to this new business model, you will both earn high income and enjoy the pleasure of adding value to the beautifying your environment. You can discover the plant and plastic mould models you will buy here. Also there are some examples of the blocks that have been designed and made before.

GET A QUOTATION QUICKLY

To own a decorative paving block manufacturing facility, you can reach our sales team 24/7 in your preferred language. All you have to do is fill out the form below and send it. Our representative will contact you as soon as possible.

PURCHASING STAGES

We have made purchasing a decorative paving block production facility as easy as purchasing products from your neighboring city in your country. We have created our entire export and commercial structure to provide this convenience. For detailed information, you can read the purchasing steps below or contact our sales representatives.

GENERAL COMMERCIAL TERMS

REVIEW

STAGE 1 – CONTRACT

REVIEW

STAGE 2 – PROJECT

REVIEW

STAGE 3 – PRODUCTION

REVIEW

STAGE 4 – SHIPMENT

REVIEW

STAGE 5 – INSTALLATION

REVIEW

WHY MEGA EXPORT & IMPORT

REVIEW

WHY STONE PRODUCTION FACILITY

REVIEW

SPECIAL GUARANTEE AND SERVICE

REVIEW

FREQUENTLY ASKED QUESTIONS (FAQ)

What is a new investment or new business opportunity?

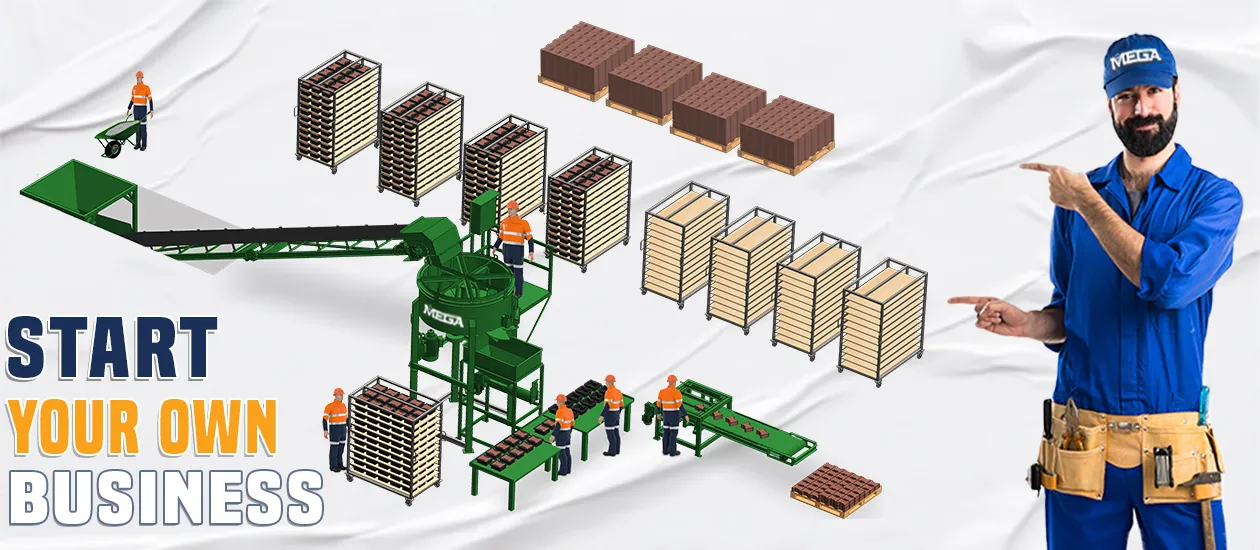

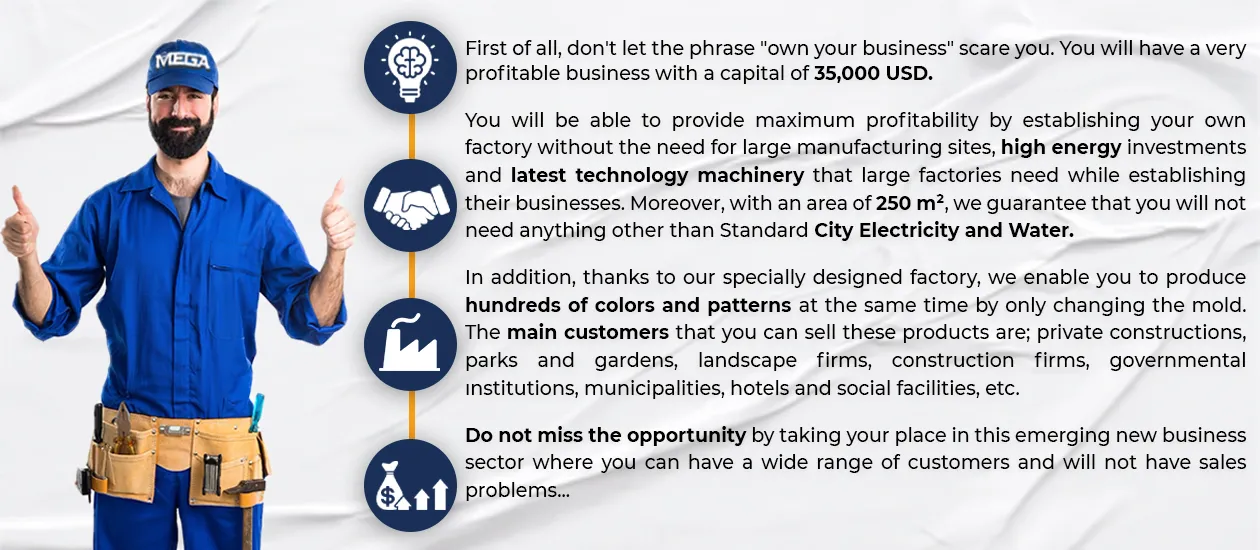

It is difficult to make new investments these days due to the high investment costs and big labor costs. In addition, since each new investment has its own risks, it causes investors to give up easily. In this new business opportunity that we offer you, we enable the production of block, which has been made with primitive methods until today, with low costs, increased efficiency, and increased earnings due to much lower labor costs.

Can I make money from this facility?

While raw material prices, which are the most affecting factor on product costs, may vary by regions, having high-profit margins for manufactured products enables the return on investment in the facility. Especially in recent times, due to the increasing demand and growth in the African market, setting up operations at low costs in foreign markets has become a sector where substantial profits can be achieved.

How much space is required for the facility?

Determining the area required for the facilities we have manufactured is directly proportional to the daily production capacity targeted. An area of 250 m² is sufficient for our facilities where the base model (150-200 m² in 8 hours) production is targeted. There is no need to cover the entire area with concrete. Especially in African regions There is no need to cover the with a roof.

How many people can work at the facility and what is its daily capacity?

At our base model (150-200 m² in 8 hours) production facilities, a maximum of 6 personnel is sufficient for manufacturing. Thanks to the automation system of our facility, the system itself does most of the work. the personnel will do the processes with the help of the control panel.

How many different decorative stones can I produce with this plant?

We have 150 different molds models in stock for the facilities we have manufactured. Regionally, we can also create custom productions to meet specific demands for different mold models. You can review our digital catalog to explore all the mold models in our inventory.

How long can I use plastic molds?

Plastic stone molds produced using premium quality pp (polypropylene) raw material allow you to produce an average of 250 decorative stones with correct use. You can increase this number much more by using mold-protecting chemicals.

Can I buy and sell your products in my region?

As our company Mega Export, we receive requests from intermediaries in many countries of the world. Due to the problems that arise in order to protect our brand value in sales made through intermediaries, we only work with companies that are our dealers, especially in European, African, Gulf and Latin American countries. You can contact us regarding your dealership requests.

The Project of the Infrastructure Preparations to be Made in the Area where the Facility will be Established is given by our company free of charge. For More Detailed Information And To Watch Promotional Videos, Visit Our Youtube Channel.

BLOCK MAKING EQUIPMENT

With the decorative paver block manufacturing plant, not only decorative paver blocks are produced. In addition, with the “Block Making Equipment” we offer you, you can produce many special concrete blocks types such as different concrete lego block, styrofoam cocnrete blocks.

It is very simple and easy to use. Fill the prepared mixture into the mould. After filling the mixture, turn the mould upside down. Then press and pull. Here is your concrete block.